Category

Automatic Rigid Box Making Machine Gift Box Product Line with Visual Positioning

Overview Product Description RB350 Automatic Rigid Box Maker RB350 is the newly developed high-speed intelligent rigid b

Overview

Features:1. Automatic servo controlled paper feeder. 2. Automatic circulation, mixing and gluing system of hot-melting glue. (Optional: glue viscosity meter) 3. Glue preheating function. (Optional) 4. Non-stop cardboard feeding and stacking. 5. Hot-melting paper tape is automatic conveying, cutting, and pasting the cardboard box corners in one process. 6. Servo driven corner pasting unit, reduce the setting time, more accurate to paste the corners. 6. The vacuum suction fan under the conveyer belt can keep the glued paper from deviating. 7. The glued paper and cardboard inner box employ Robot and camera positioning device. 8. Double wrapper unit, according to the conveying situation of the boxes above the conveyor belt, take the boxes to the wrapper unit in turn. 9. The wrapper can continually delivery boxes, wrap, fold ears and paper sides, form and press the box in one process. 10. It adopts 51sets servo and 14 sets stepping motor which realize the full automatic adjustment, data can be stored.

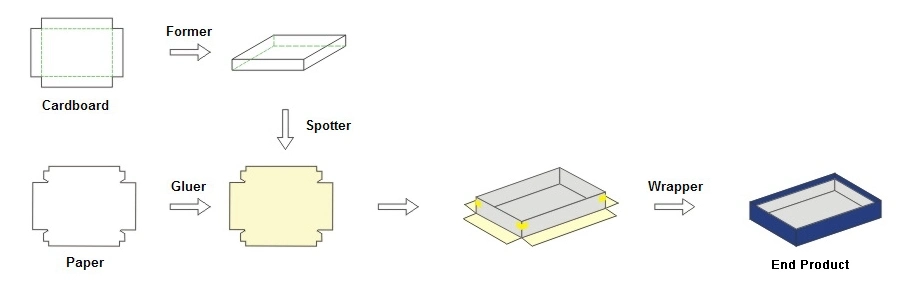

Production flow:

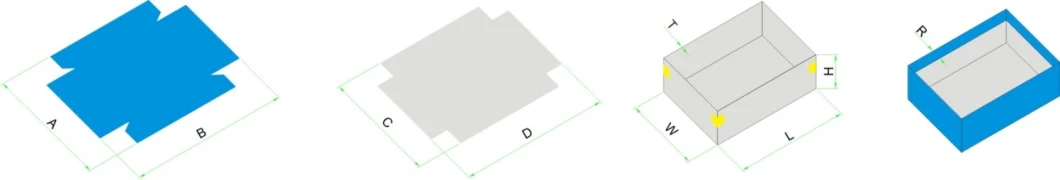

The corresponding relationship between the parameters:W+2H-4T≤C(Max) L+2H-4T≤D(Max)A(Min)≤W+2H+2T+2R≤A(Max) B(Min)≤L+2H+2T+2R≤B(Max)

Main Technical Parameters:

Paper type:Sample:About Us

Basic Info.

| Model NO. | RB350 |

| Automatic Grade | Automatic |

| Precision | 0.10mm |

| Speed | 55sheets/Min |

| Cardboard Stacking Height | 1100mm |

| Paper Stacking Height | 630mm |

| Air Supply | 50L/Min 0.6MPa |

| Machine Weight | 6000kg |

| Heater Power | 10kw |

| Motor Power | 30kw/380V 3phase |

| Box Height(H) | 10-100mm |

| Box Size(W*L) | Min. 30*50mm, Max.250*350mm |

| Cardboard Thickness(T) | 0.8-3mm |

| Fold-in Paper Size(R) | 10-90mm |

| Name | Rigid Box Machine |

| Model | Rb350 |

| Paper Size(a*B) | Min.70*130mm, Max. 460*600mm |

| Transport Package | Wooden Pallets/Cases |

| Specification | L6300*W5200*H3200mm |

| Trademark | Rongda |

| Origin | Wenzhou, Zhejiang, China |

| HS Code | 84414000 |

| Production Capacity | 10set/Month |

Product Description

Product Description RB350 Automatic Rigid Box Maker RB350 is the newly developed high-speed intelligent rigid box machine. It employs high speed motion controller, PLC programmable controller, Robot &camera positioning system, pneumatic system, HMI and remote monitoring system to automatically finish feeding and gluing paper, conveying cardboard, forming and pasting four corner of cardboard, positioning and bonding, and wrapping box in one time. Effectively replace manual production, greatly improving production efficiency and quality of finished boxes. It is applicable to make high-end boxes for mobile phones, shoes, shirts, cosmetics, perfume, mooncakes, sweets, chocolates, liquors, cigarettes, tea, etc.

Features:1. Automatic servo controlled paper feeder. 2. Automatic circulation, mixing and gluing system of hot-melting glue. (Optional: glue viscosity meter) 3. Glue preheating function. (Optional) 4. Non-stop cardboard feeding and stacking. 5. Hot-melting paper tape is automatic conveying, cutting, and pasting the cardboard box corners in one process. 6. Servo driven corner pasting unit, reduce the setting time, more accurate to paste the corners. 6. The vacuum suction fan under the conveyer belt can keep the glued paper from deviating. 7. The glued paper and cardboard inner box employ Robot and camera positioning device. 8. Double wrapper unit, according to the conveying situation of the boxes above the conveyor belt, take the boxes to the wrapper unit in turn. 9. The wrapper can continually delivery boxes, wrap, fold ears and paper sides, form and press the box in one process. 10. It adopts 51sets servo and 14 sets stepping motor which realize the full automatic adjustment, data can be stored.

Production flow:

The corresponding relationship between the parameters:W+2H-4T≤C(Max) L+2H-4T≤D(Max)A(Min)≤W+2H+2T+2R≤A(Max) B(Min)≤L+2H+2T+2R≤B(Max)

Main Technical Parameters:

| Model | RB350 | |

| 1 | Box size(W×L) | Min. 30*50mm, Max.250*350mm |

| 2 | Paper size(A×B) | Min.70*130mm, Max. 460*600mm |

| 3 | Box height(H) | 10-100mm |

| 4 | Turn in depth(R) | 10-90mm |

| 5 | Cardboard thickness(T) | 0.8-3mm |

| 6 | Paper thickness | 100-300gsm |

| 7 | Precision | ±0.10mm |

| 8 | Speed | <55sheets/min |

| 9 | Power | 30kw/380v 3phase |

| 10 | Air supply | 50L/min 0.6Mpa |

| 11 | Machine dimension | L6300×W5200×H3200mm |

| 12 | Machine weight | 6000kg |

| 13 | Paper type | 1/2/3 |

Paper type:Sample:About Us